Automated Dry Mixed Mortar Production Line

Introduction

Through many years research and experiences in dry mortar production, MUHU has established mature technology in dry mortar production, which can be widely applied in the producing of masonry mortar, plastering mortar, heat preserving mortar, high strength no shrinkage grouting material, cement-based and epoxy-based floor hardeners, repair mortar, cement-based tile adhesive, self-leveling mortar, repairing mortar. Further more, it can be used in the mixing of concrete admixture powers.

This production line is computerized. It can automatically control the raw material selecting, weighing, and packing. It increases the product quality, reduce labor cost, and has less (or no) dust pollution. Generally, the profit of mixed dry concrete products are very profitable, about two times high than the cost of raw materials.

Advantages

- Automatic measurement enormously improves product quality;

- Closed production greatly lowers down the environmental pollution.

- Automatic material transfer reduces the labor intensity and improves efficiency

Instruction for Equipment

The design of the equipment depends on customer’s different need, which include: products output from three tons per hour to one hundred tons per hour , the automatic level of the equipment such as from manual material calculating to automatic calculating, manual packing to automatic packing.

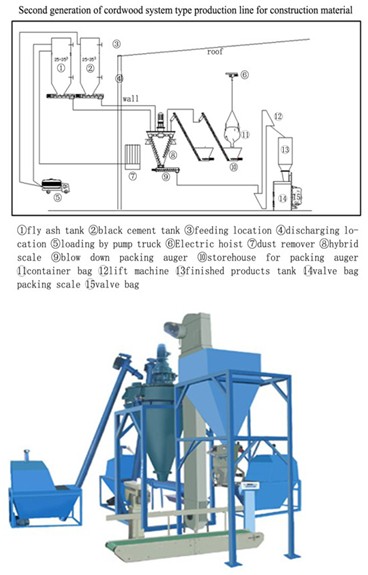

1. MH-GS cordwood type computer-controlled mixing machine group

Cordwood type structure of mixing machine has following features:

1.1 It is operated by man-computer interface, with weighing transducer coordinating with PLC automatic computer feeder,

1.2 It can memorize the formula, record the historical data and print them out.

1.3 It can show the on-site location of raw material tank by computer.

1.4 Automatic measuring packing (valve bag, spacious bag)

1.5 Dust remover can improve the working environment, recycle powder material

1.6 Less space taken, flexible structure combination, low cost, available in small-lot serial production

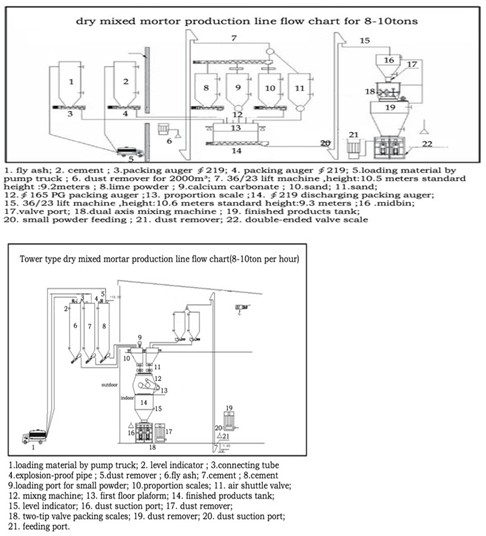

2. MH-GS tower type dry mixed mortar mixing machine group(8-10t/h)

2.1 It is operated by man-computer interface, with weighing transducer coordinating with PLC automatic computer feeder,

2.2 It can memorize the formula, record the historical data and print them out.

2.3 It can show the on-site location of raw material tank by computer.

.2.4 Automatic measuring packing (valve bag, spacious bag)

2.5 Dust remover can improve the working environment, recycle powder material

2.6 Less space taken, flexible structure combination, low cost, available in small-lot serial production

Production Process

- Batch different kinds of raw material according to formula

- Put the batched material into the mixer

- Start the mixer and run it in specified time period

- Convey the mixed products into the finished product warehouse and automatically start weighing and packing

- After quality inspection, the products will be stored in warehouse.

Project investment

- Equipment cost: 20,000USD – 100,000USD (The cost will varies with customer’s requirement);

- Operator: two to five;

- Manufacturing know-how: 45000USD

- Construction Period: about 45 days after the equipment arrived;

- Project services: totally turn key project.

MUHU will be in charge of the compressive technical guidance, the facility user purchase and Install the equipments

Applications Projects

1.Wuhan

In June, 2010, MUHU technical team finished installation and commissioning of dry mortar production line for a Wuhan customer, provided product formula that met local market and offered staff training.

2.Indonesia

In Nov. 2013, MUHU technical team finished installation and commissioning of dry mortar production line for Indonesian customer, provided product formula that met local market and offered staff training.